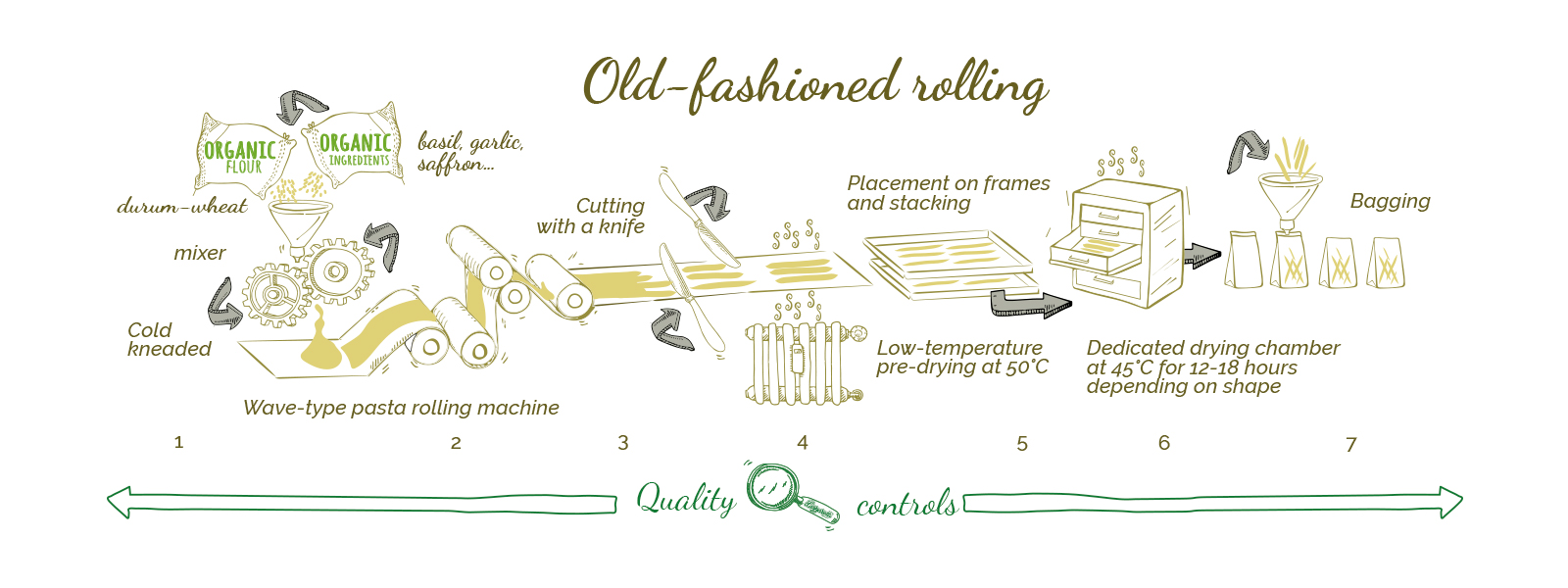

Old-fashioned rolling

For flavour and quality similar to fresh pasta.

Less and less popular with manufacturers, this method may be low-automation and low-yield but offers definite flavour benefits.

As with home-made pasta flattened with a rolling pin, this traditional manufacturing method, the dough is not subject to high pressure or a significant rise in temperature.

The semolina is mixed slowly with water, eggs and the recipe’s other ingredients. Then, our pasta craftsmen decide when the dough reaches the ideal texture for rolling! The pasta is then flattened by successive rollers, and cut with a knife. The dough is rolled so thinly that our pasta needs to cook for barely 5 minutes!

All our Tagliatelle and Butterfly pasta are cold rolled until very thin, so they taste as good as fresh pasta.

-

The organic durum-wheat flour and other ingredients (basil, garlic, spirulina, saffron…) are poured into a mixer and cold kneaded

-

Wave-type pasta rolling machine

-

Tagliatelle being cut with a knife

-

Low-temperature pre-drying at 50°C

-

Placement on frames and stacking

-

Dedicated drying chamber at 45°C for 12-18 hours depending on shape

-

Our organic pasta are then bagged!

Did you know?

With artisanal pasta, the quality of the organic cereals but also the old-fashioned rolling ensures unrivalled flavour and quality – so you can serve it like fresh pasta.

Close-up on wave-type pasta rolling machine

Tagliatelle being cut with a knife